Distribution & Warehouse Capabilities

COMMITMENT TO QUALITY

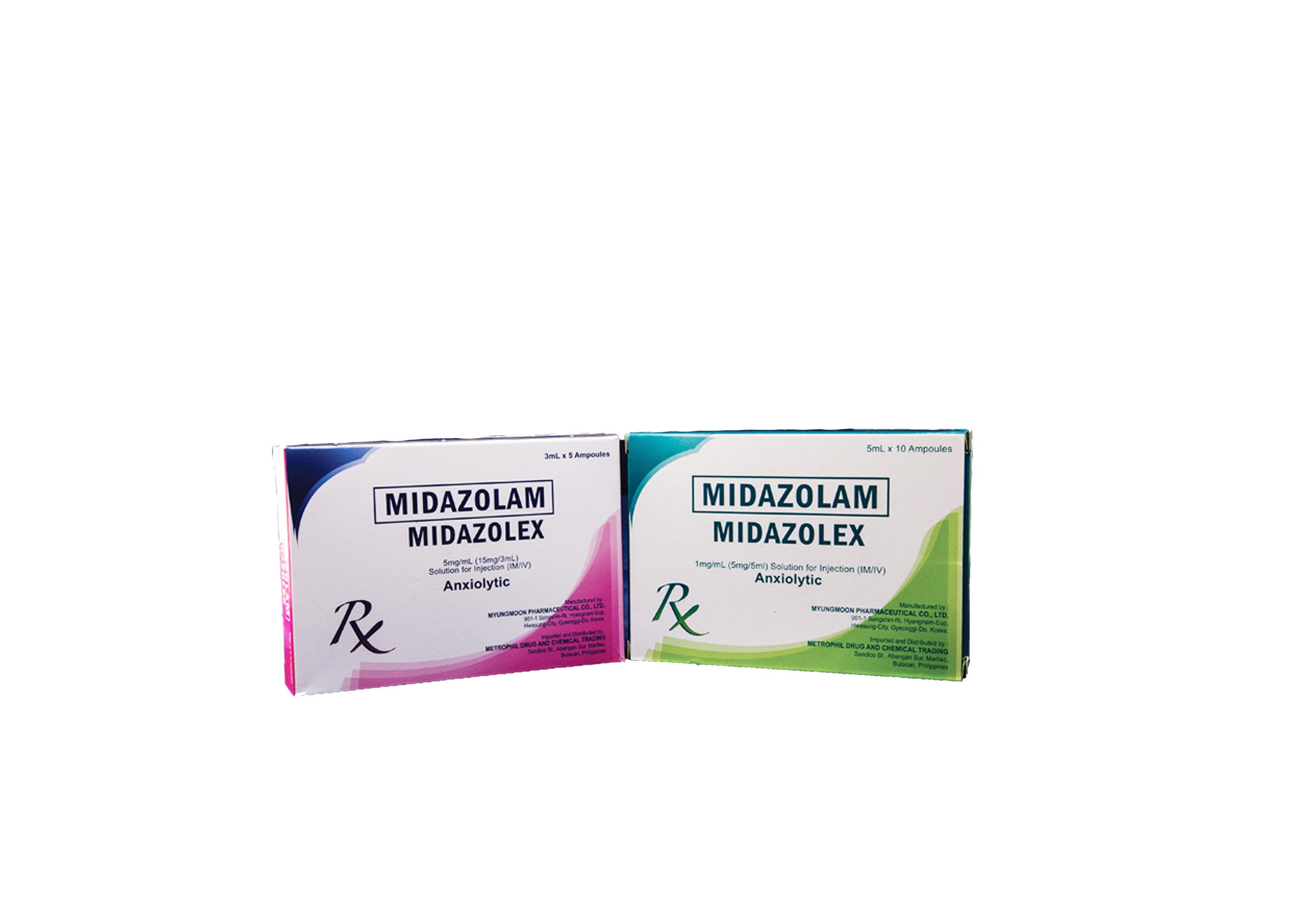

We value the significance of proper handling of our products from suppliers’ research and development to its acquisition. This measure assures quality and systematized production, as we provide standard critical care solutions towards the advance treatment of severely ill patients. Safety, efficiency, and efficacy are always a priority in our supply chain management. Our products are stored in facilities that are compliant with pharmaceutical products warehousing standards. Delex Pharma has always been and will always perform best anytime in serving its clients and partners.

PRODUCT DISTRIBUTION CAPABILITIES

Critical care products demand in the hospital sector is rising in the country. With this, responsive product distribution is vital to the emergency needs of hospitals. Thus, in 2012, the distribution business of Delex Pharma transpired. As promptness is a trait the company merits, its distribution capability aims to respond to the urgent needs of hospitals in the Greater Manila Area.

The company has its own Trade Sales Team to strengthen an organized ordering system and distribution process. Distribution management is simplified effectively through the professional works of the highly-trained team. Moreover, we implemented the use of Systems Applications and Products- Enterprise Resource Planning or SAP ERP for Order Processing & Inventory Control Management. Our Trade Sales Team has real-time information access to products in inventory. Hence, we can respond to customers' requests on time. This avoids product stock unavailability on the customer end, especially in critical times.

With a centralized system in the company, we can execute process effectively from the procurement planning to the distribution of our products. Thus, it increases our productivity while we deliver satisfaction to our clients.

As we aim to respond with urgency, we practice flexible delivery lead time for National Capital Region areas and nearby provinces. Our experienced delivery crews are passionate about providing excellent experience among our customers. Since we prioritize product safety, our people always observe the utmost care in handling our products.

Part of our distribution operations is the required usage of standardized delivery vans. Air-conditioned Mitsubishi L300 Delivery Vans are the safe transportation mode of our products. Aside from the class vans are the motorcycles with insulated storage boxes and Mobile Data Loggers for Temperature & RH monitoring during transit. Our staff transfers the items from the warehouse to the vans by Hydraulic Order Picker and Hydraulic Pallet Trucks. It offers proper handling of our products while being transferred to the delivery vans. As we adhere to the strictest safety protocols, we use 100% Plastic Pallet to prevent termite infestation. Backing us up in our prompt delivery are our reliable third party logistic networks, namely LBC Express, W Express, and 2GO Express.

Along with technological advancement initiatives of the company is the integration of an e-commerce distribution platform. It will provide a comprehensive model of a transaction between Delex Pharma and its clients. It aims to achieve competitive and sustained growth in product distribution.

While we are braving a health crisis, Delex Pharma adapted to the evolving trend of customer service by launching the Telemarketing department. This method will sustain the efficiency and efficacy of client servicing amidst the COVID-19 pandemic.

To avoid the supply chain limits during this crisis, we re-opened our VISMIN depots in Iloilo, Cebu, and Davao. It allows the undisruptive supply of critical care drugs in the hospital, especially during the first month of lockdown in GMA.

We execute organized distribution protocols, which are compliant with the regulations imposed by the Philippine government agencies. The company implemented the skeletal workforce system among warehouse personnel to address continuous distribution operations. It limits the staff who are working inside the facility to avoid possible virus infection. As we abide by the safety measures, assigned staff strictly observe the use of the face mask and laboratory suit while inside the warehouse facilities. They are firm in social distancing while at work. DPI also ensures the safety of the workers. Thus, it provides a shuttle service to avoid the exposure of employees in public transport where virus spread is high. Moreover, all facility personnel is required to provide details for the health checklist for monitoring. Furthermore, the team is closely working with the Regulatory Department to ensure compliance with government regulations on product importation and other legalities amid the pandemic. As cashless payment is endorsed for transactions in this new normal, our team initiated an e-commerce platform in collaboration with the IT and Finance Department.

In response to the delivery process, our telemarketers maintain effective shipment protocols before our clients will receive the products. The riders of the company always observe proper delivery guidelines for the safety of products and customers. The products undergo sanitation before transporting. They also use new personal protective equipment upon the dispatch of life-saving medicines.

Through this effort, Delex Pharma can minimize the risk of disruption as it secures supply chain resiliency while it continues to provide quality critical care products to its market.

COLD STORAGE FACILITY

Delex Pharma International, Inc. operates a Walk-in Chiller for storing oncology products at 2°C to 8°C. The Chiller, measuring 100 cubic meters (L6m x W4m x H4m), uses two 3.0HP condensers on a weekly rotation to ensure full functionality. Quarterly preventive maintenance is performed, and a calibrated Data Logger records the temperature every 5 minutes, with cloud storage provided by the device supplier.

Products are picked and packed inside the Chiller, wrapped in bubble wrap, and sealed in 1-inch thick Styrofoam with ice-gel packs to maintain the required temperature. A corrugated box is used for final packaging. Orders are only removed from the Chiller when the delivery rider is ready, and dispatch occurs only when the delivery date and time are confirmed by the recipient.

The facility is supported by a robust generator system to ensure an uninterrupted power supply, maintaining optimal temperature from dispatch to delivery. This commitment to quality ensures that our clients receive products meeting the highest standards, essential for patient care and treatment.

Warehouse Capabilities

With notable growth in recent years, DPI has upgraded its warehouse and distribution capabilities to enhance service excellence. It has leased three warehouses, totaling 1,224 square meters, to accommodate its expanding portfolio, which includes both medical drugs and devices, ensuring efficient storage and delivery.

Currently, DPI's warehouses have achieved ISO 9001:2015 re-certification this July 2024 and have passed procurement inspections by Joint Commission International (JCI) accredited member hospitals such as St. Luke's Medical Center (Quezon City & Global City), Makati Medical Center, The Medical City, and Asian Hospital Medical Center.

Customer satisfaction is a top priority. We ensure timely deliveries, with a one-day delivery time for the Greater Manila Area (GMA) and a 3-5 day delivery time for all provincial areas.

We have a main warehouse, which measures 665 square meters with a mezzanine. As the demand for critical care items continue to peak, we rented another 425 square meter warehouse. Product safety is assured as we execute effective and reliable warehouse operations. In response to product quality checks, our main warehouse has an organized quarantine area for inspection, packing, and receiving process. The expired and damaged products are properly placed in designated areas. Moreover, our facilities are equipped with the necessary accessories and features that are critical to warehouse management.

Air Conditioned Distribution Office & Storage Areas

WiFi Data Loggers for Temperature & RH monitoring with remote viewing capability

24/7 CCTV Surveillance: Interior & Exterior of Warehouse with Remote Viewing Capability

Fire Alarm & Smoke/Heat Detection System

Fire-Fighting System

Standby Generator Set

24/7 Security